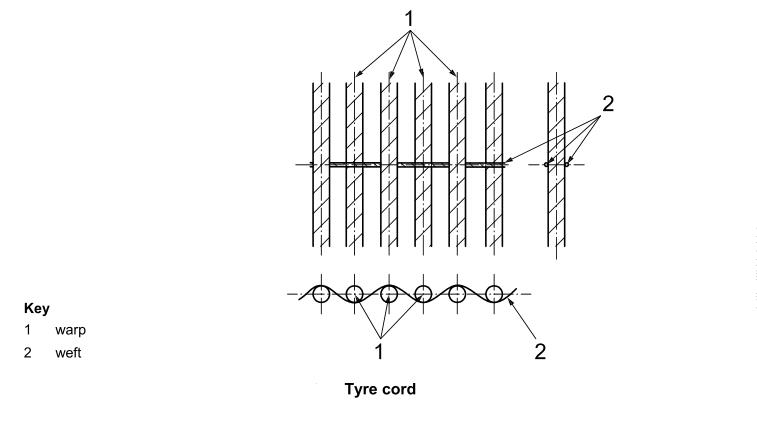

1. Material: Natural Rubber and Nylon Cord

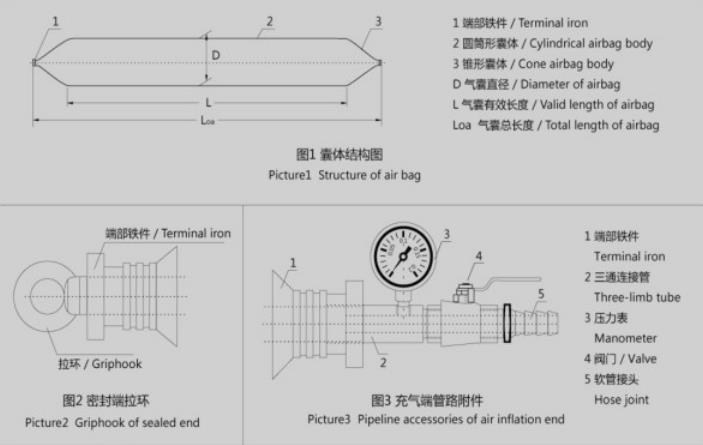

2. Fittings: Inflation Valve, Pressure Gauge, Pulling Ring

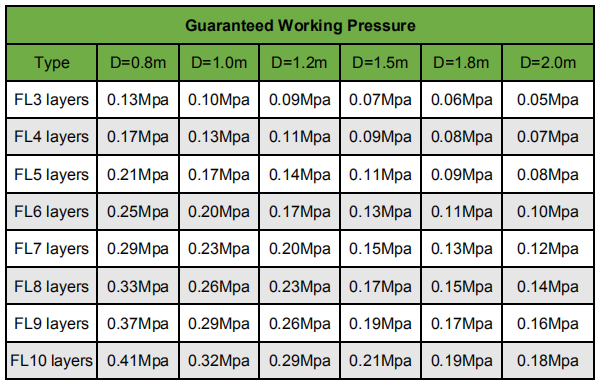

3. Layers Range: 3-12 Layers

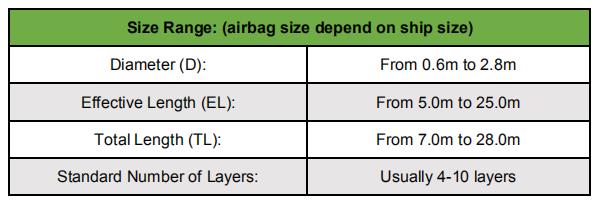

4. Size Range: Dia 0.6-2.8m, Len 5.0-25m

5. Service Life: 5-8 Years

6. Certs: CCS, BV, ISO, RS, ABS, Etc

We would be pleased to advise you personally or send you further information.

Contact Us

1. Material: Natural Rubber and Nylon Cord

2. Fittings: Inflation Valve, Pressure Gauge, Pulling Ring

3. Layers Range: 3-12 Layers

4. Size Range: Dia 0.6-2.8m, Len 5.0-25m

5. Service Life: 5-8 Years

6. Certs: CCS, BV, ISO, RS, ABS, Etc

Overview

Overview

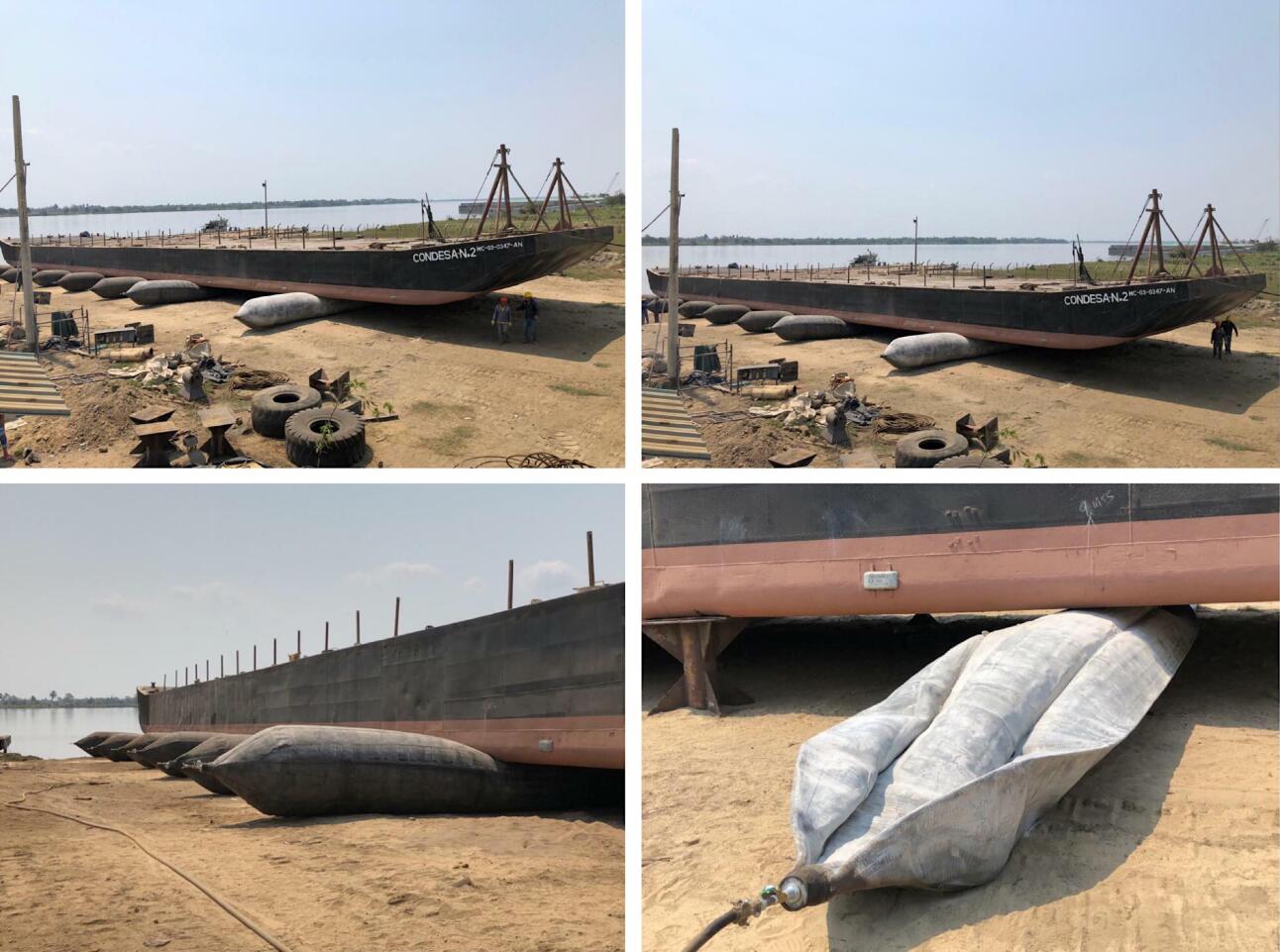

Florescence ship rubber airbag comply with ISO 14409. ship airbag can be used to launch and upgrade a ship up to 100,000DWT. Comparing to the traditional slipway launching method, the ship launching airbags are much environmental, because ship airbag can launch a ship at any seaside, so there's no need to worry about the construction of launching facilities; besides, the marine airbag need little maintenance and can be used repeatedly.

Features

●Different airbag size stock available, quick delivery

●Provide repair kit and on site instruction

●Long time service life can be reused many times

●Wear resistance and anti aging

●Good raw material and cord fabric

●Do no harm to the environment. Time & money saving

●Need no more than air compressors, winches and ropes

●Marine airbags are much cheaper and portable than other methods

Application

1.For ship upgrading, conversion or new/repair launching (Ship launching airbags)

2.Marine airbag for salvaging sunken ship or heavy immersed steel structure

3.For hoisting and transporting heavy goods up to 10,000 tonnes structure on land

4.For floating use purpose as improve the draft.

5.Pneumatic rubber core for architecture engineering Container for storing and transporting gas and corrosive chemical liquid and pure water for voyage

6.Rubber bag for ship ballast

7.Rubber airbags used for culvert making.

Marine airbags are also known as ship launching airbags, ship docking airbags, marine launching airbags, marine upgrading airbags, air bladders,ship lifting airbag,ship rubber airbags,rubber tube,ship salvage airbags, rubber pontoon, inflatable air bags, air lifting bags, air balloon,salvage bags,ship launching rubber airbag.Airbags now are used for ship launching ,loading and floating,they are widely used in cargo/boat /ship/vessel launching and landing,lifting and moving sunken ships and heavy goods.

Structure of The Florescence ship launching airbags

Please the picture 1 of Florescence inflatable rubber airbag structure . It is composed by airbag body and terminal iron part. The airbag body is composed by natural rubber and strength fiber material through vulcanization processing; The terminal iron part is made of cast iron, it is combined closely with the bag body; One end is for pulling when move the airbag, and the other end is for charging and discharging the air. All the fittings in picture 2 and 3 will be supplied with airbags for free.

Materials

An airbag is to be constructed of an outer rubber layer, one or more synthetic-tyre-cord layers, and an inner rubber layer. The arrangement of synthetic-tyre-cord reinforcement layers is shown in the picture below, all materials shall be vulcanized firmly.

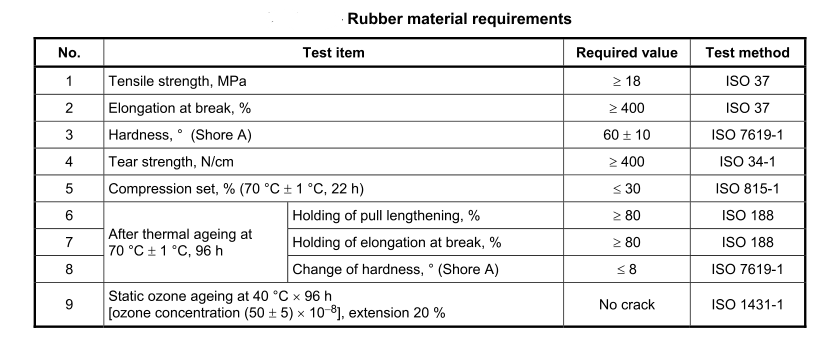

Prior to the airbag production, the outer and inner rubber layers shall be tested to meet criteria in the following table in accordance with the test methods given in the international standard list in the table. While only one satisfactory sample per batch is required for test numbers 1 through 3, all others must be tested for test numbers 4 through 9 annually. If the first sample fails, two additional sample should be tested. If the additional samples pass the test requirements, the materials will be deemed to have passed the test. Otherwise, the materials will be deemed to have failed the test and another batch of materials shall be selected.

Procedure of Launch a ship by rubber airbags

1.Pre-launch preparation work for shipyard

Slipway Enhancement

Water survey

Vessel skeg enhancement

Ground anchor

Seal thruster holes if there are.

2.Basic equipments needed for ship launching

Rigging equipments:Winch,Pulley,Swivel,Lug, Shackle, Wire sling,Ground Anchor

Inflate equipments:Air Compressor,Inflating Pipe

Airbag moving equipments:Forklift,mobile crane

3.Crew preparation

4.Rigging Arrangements

5.Lifting the blocks

6.Move vessel forward

7.Vessel Launching

The requirements of launching ship and relevant equipments.

1.Ship

The engineering work under water line shall wholly be finished, especially those equipments, valves and others that are to be installed at the openings under ship waterline,the installations should be approved by inspection. All the burrs, welding beading and the like on the ship bottom or appendages should be ground away. All the welds on the shell plate must pas inspection and tightness test. The main dimensions of the ship should be measured up and the mark of loadline must pass inspection. All the paint work of the shell plate has been finished.

2 Ramp way

The ramp way on which the airbags will rolling should be cleaned and be clear of sharp fends such as iron nail. The ramp way should be leveled and the level error from left to right should less than 80mm. The ground caved in should be filled up and the ground bearing capacity should be relatively equalized. The ramp made of mud land, sanded land, sands or concrete, however, its bearing capacity should be twice as big as the working pressure of airbags. The slope of ramp is to be determined according to the size of the launching ship and is generally no bigger that 1/7. In the range of the whole length of the ramp way, the shape may be of multiple combination with slope line, are line and others. However, the ship bottom should not contact the ground even when the airbags are at their lowest working height. The ramp way should extend into water for certain length.

3.Winch

In general, a slow winch is to be selected, its veering speed is about 9-13/m/min. The moving speed of a ship must not be more than 6m/min with the control of hauling force of winch wire. If the ship weight is less than 200t, the moving speed can be increased properly. The wire must be inspected and replaced regularity.

4.Air compressor

The type and capacity of the air compressor is to be selected according to the total volume of all the airbags provided for the launching and time required for air filling and the air pressure. The gas tank of air compressor should be installed with adjustable pressure limiting valve.

Safety precaution

● Over pressure Control:

Strictly control the operating pressure, over pressure is forbidden.

● The Landing Slipway Requirements:

The landing ground should be ground or cement concrete, according the tonnage of different ships.

● Avoid Sharp Objects:

Make sure no sharp objects and make sure the smooth and clean ground during using them in case of break of airbag.

● Avoid Distortion And Overweight

Avoid distortion in the length direction during rolling and avoid overweight load after gas charging.

Storage

● When the airbags are not to be used for a long time, they should be drained, cleaned, dried, filled with talc power, and the exterior surfaces should be coated with talc power.

● The airbags should be maintained in a dry ventilated room and be protected from light.

● The airbags should be in a relaxed condition free from tension, compression or other deformation.

● The airbags should be kept away from any heat source.

● The airbags should be protected from acids, alkalis, oils or organic solvents.

We guarantee you that we do not store any more data than is required for the services provided. We do not pass this data on to third parties outside the Qingdao Florescence Marine Supply Co.,Ltd All information will, of course, be treated confidentially.

Back