We have successfully completed the delivery of 28 sets of cone fenders 1050H to our Sri Lanka customer for their upcoming construction project at the SAGT Port.

Our company is very honored to participate in this project. In the early stage of the project, our engineering team represented by Mr. Turise Liu conducted analysis, research and design based on multiple aspects such as docks, ships and berthing. After discussions with the customer, the cone fender solution was finally confirmed.

Cone rubber fender, as an important anti-collision device for ships and docks, has the following remarkable features:

1. Unique structural design:

The conical design enables it to disperse and absorb the impact force during collision more effectively.

2. High-quality materials:

The main material is rubber, which has good elasticity and wear resistance.

3. Easy installation:

It reduces construction time and cost, making the installation of conical rubber fenders more convenient.

In summary, cone rubber fenders play an important role in port construction with their unique characteristics and significant advantages. They not only provide safer and more efficient protection and services for docks and ships, but also reduce maintenance costs, and improve the durability and anti-seismic performance of equipment.

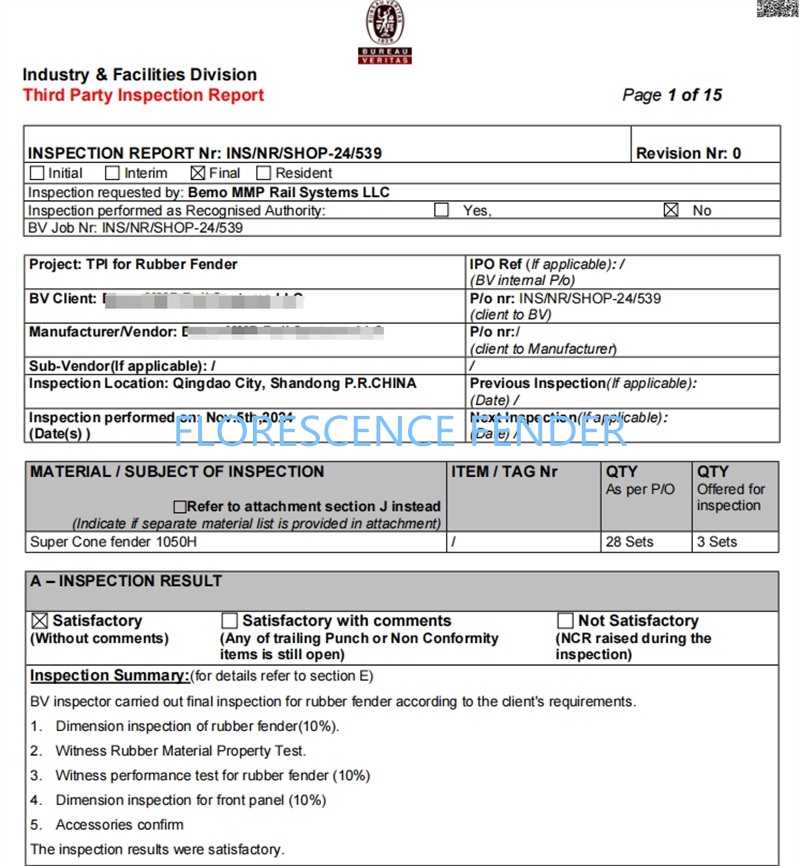

After the 28 sets cone fenders were completed, BV surveyor conducted tests and all were qualified. The customer was very satisfied with the quality of our cone fenders and services. Before shipment, we conducted a comprehensive inspection and packaging, and 28 sets of cone rubber fenders were loaded into 4*40HQ containers and sent to Sri Lanka smoothly.